Reverse Engineering for NX CAD

WLS Adaptive Reverse Engineering — Inside NX CAD

Scan-to-CAD Adaptation — Native Inside NX CAD

Close the gap between your CAD models and physical reality — without leaving Siemens NX. Import scan data, identify deviation areas, and adapt your geometry to match what's actually been manufactured.

Ideal for correcting production drift on automotive body panels and complex curved components. The fully associative workflow means corrections propagate through your design tree automatically — no manual rework, no external data exchange, no broken references.

Request DemoKey Capabilities

- ✓ Direct STL scan data import

- ✓ Intelligent deviation detection

- ✓ Associative correction propagation

- ✓ Production-ready output

- ✓ No external data exchange required

See Reverse Engineering in Action

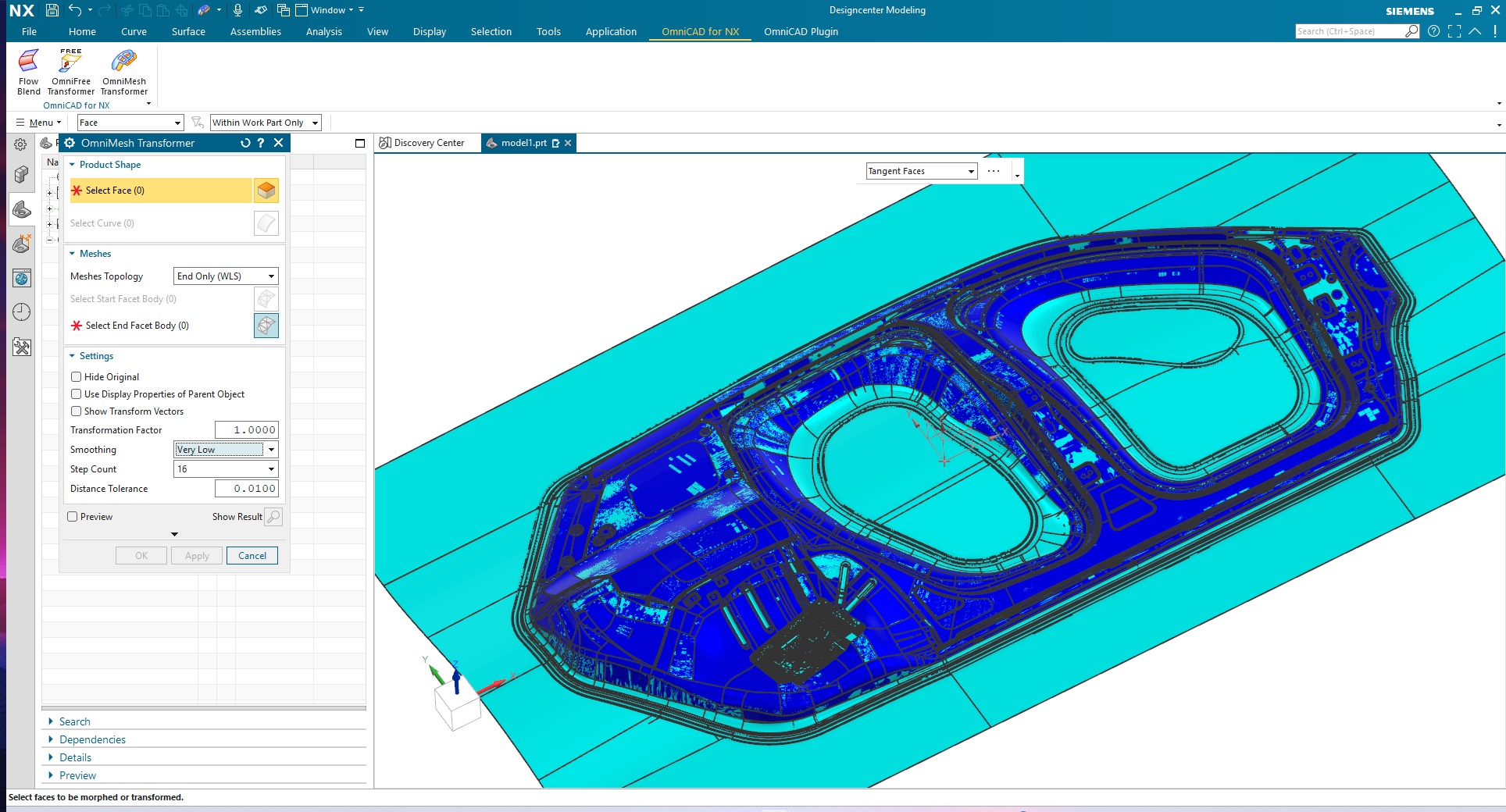

Scan-to-CAD morphing inside Siemens NX: import and clean STL scan data, then use Mesh Transformer's deformation parameters to adapt CAD models to real-world measurements.

Adapt CAD surfaces to match STL scan data for automotive body panels: select deviation areas and apply mesh transformation with customizable smoothing to correct geometric differences.

Accelerate your reverse engineering workflow

See how WLS transforms scanned data into production-ready CAD — directly inside NX.