Reverse Engineering (WLS)

Adaptive Reverse Engineering

Close the Gap Between Design and Reality

Manufactured parts never perfectly match their CAD models. WLS closes that gap — adapting your existing geometry to match actual scan data, so your digital twin reflects what's really on the shop floor.

Built into the Mesh Transformer module, WLS imports scan data and intelligently morphs your reference geometry to match the target shape. The result: precisely aligned models ready for downstream analysis, tooling correction, or quality documentation — without rebuilding surfaces from scratch.

Request DemoKey Capabilities

- ✓ Scan-to-CAD alignment

- ✓ Works with existing reference geometry

- ✓ Intelligent surface adaptation

- ✓ Production-ready output

- ✓ No manual surface rebuilding

See WLS in Action

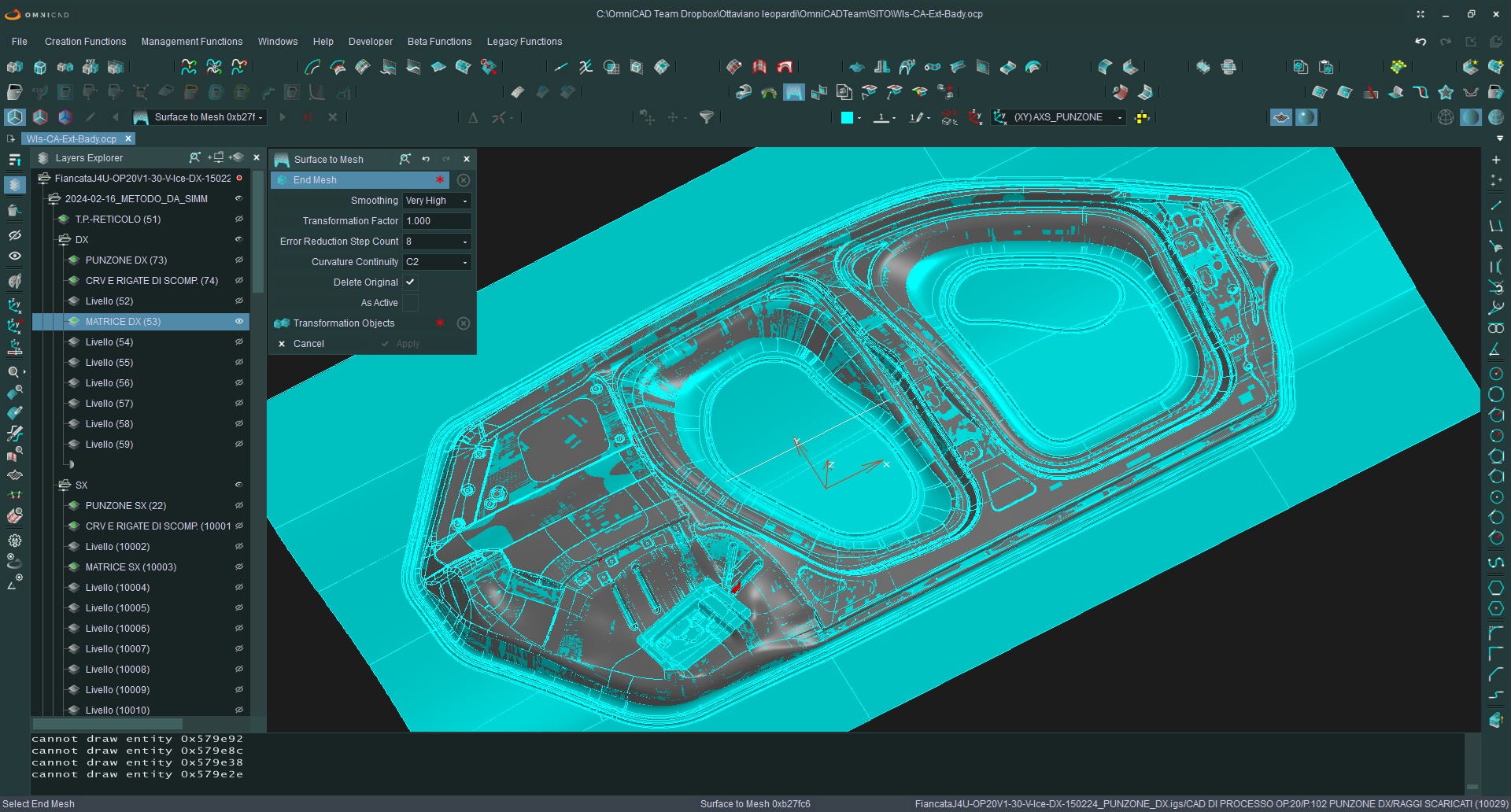

Adapt existing 3D mesh parts to match new scan data: import STL scans, configure deformation parameters including transformation factors and smoothing settings, and generate precisely aligned mesh geometry.

Why WLS?

Adaptive Approach

Combines scanned data with reference geometry for optimal results.

Faster Workflows

Dramatically reduces the time needed for reverse engineering projects.

Production Quality

Generates CAD surfaces ready for manufacturing and tooling.

Accelerate your reverse engineering

See how WLS transforms scanned data into production-ready CAD.