Mesh Transformer

Fully Automated CAD Reconstruction

The Industry's Most Effective Springback Solution

Springback kills part accuracy and drives up tooling costs. Mesh Transformer eliminates this problem — delivering first-time-right compensated tooling that dramatically reduces die tryout iterations and time to production.

Unlike manual compensation approaches, Mesh Transformer fully automates the process: from simulation data to production-ready geometry in a fraction of the time. Its unique Copy Transformer capability propagates corrections across entire assemblies, ensuring perfect fit between related components — from bumper covers to instrument panels.

Request DemoKey Features

- ✓ Fully automated compensation workflow

- ✓ Assembly-level deformation propagation

- ✓ Sheet metal and plastic molding support

- ✓ Direct CAE simulation integration

- ✓ Surface continuity preservation

- ✓ Proven across major automotive OEMs

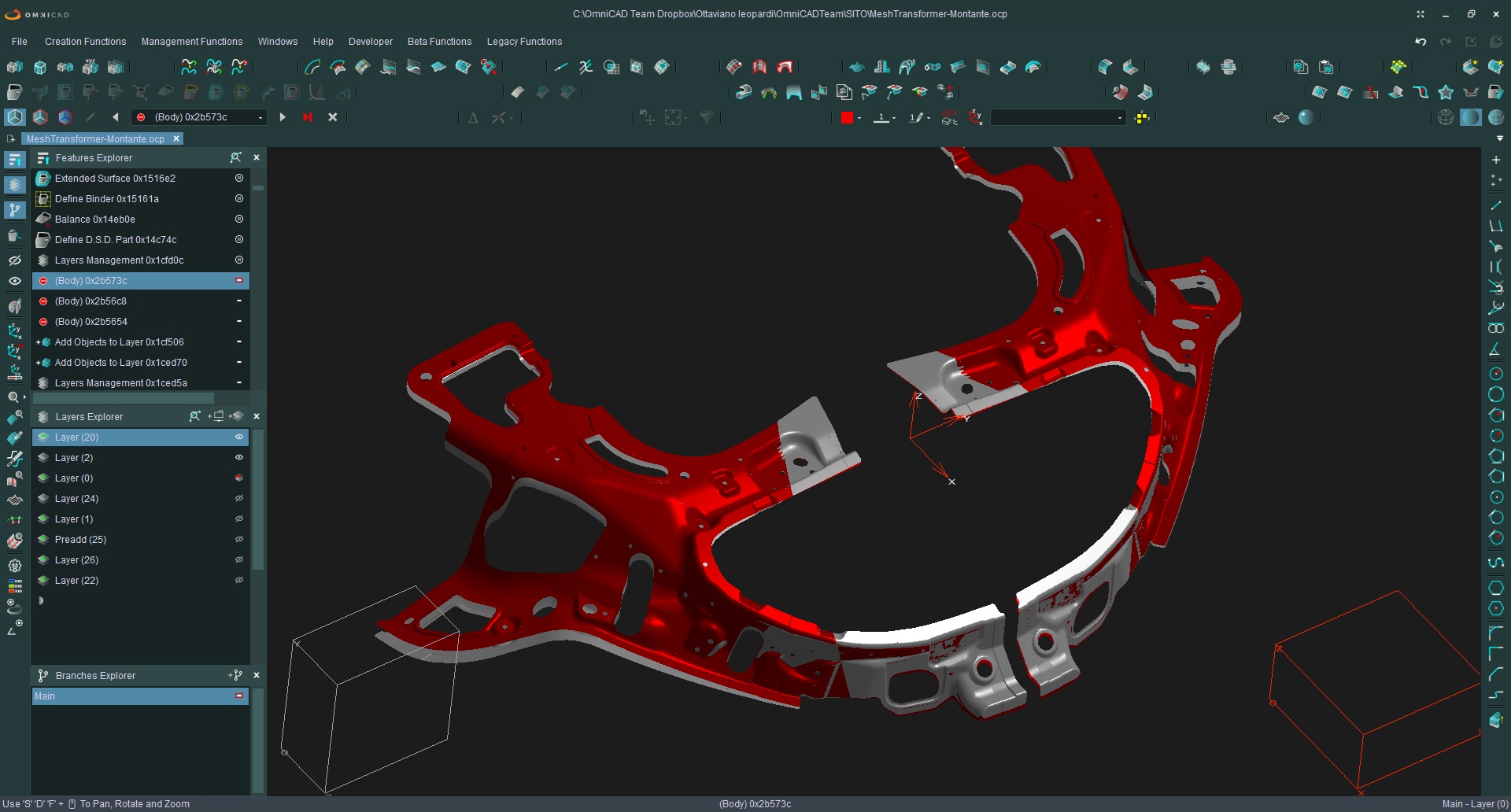

See Mesh Transformer in Action

Complete springback compensation workflow for plastic molding: import warpage simulation data, apply Mesh Transformer with negative factors to create compensated tooling, then propagate deformations to related assembly parts using Copy Transformer.

Advanced springback compensation using forming simulation data: import STL meshes, morph surfaces in the opposite direction of springback, and propagate compensation to additional components. The parametric feature tree automatically regenerates all downstream design elements.

Why Mesh Transformer?

Automation

Eliminates manual iteration. The algorithm handles complex surface deformations automatically.

Precision

Achieves first-time-right manufacturing by accurately predicting and compensating springback.

Time Savings

Dramatically reduces die tryout cycles and accelerates time-to-production.

Ready to eliminate springback problems?

See Mesh Transformer solve your most challenging compensation scenarios.